Charlesworths have new tooling which now enables us to re-mould your original worn / cracked classic Land rover or vintage spoked (banjo) steering wheel rim in the original ebonite material.

If your classic Land Rover 17″ Bakelite type steering wheel is cracked, broken or leaches black & sticky when wet or damp we can help to refurbish it.

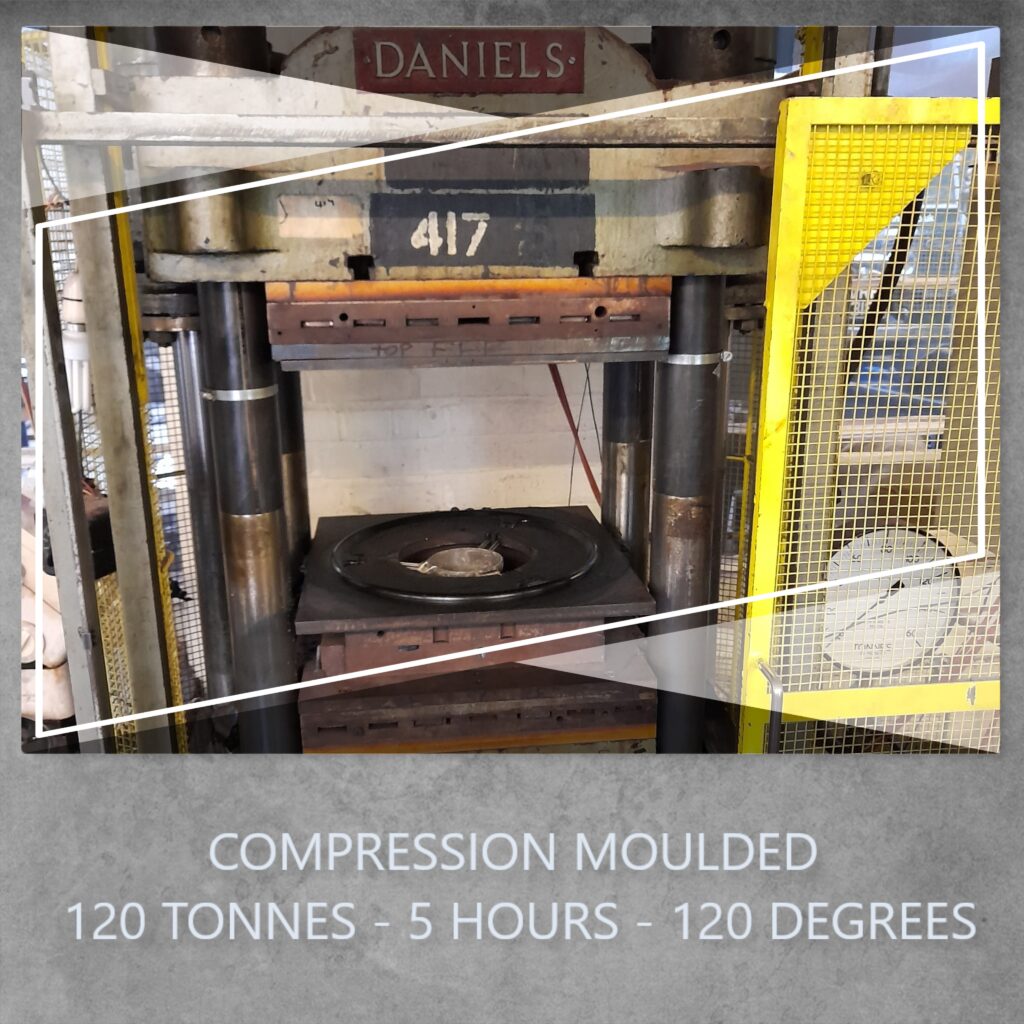

After removing the existing cracked material (often referred to as Bakelite) from your wheel we can mould a new rim covering in it’s place.

This process allows us to replace all of the old material with new, without the need for fillers.

Our guide for Land rover steering wheel removal

The small print bit:

Please contact us: Email or phone 01675 470382 for more information & pricing.

We are only able to carry out this on 17 inch outside dia wheels at the current time.

It is up to you to supply us with with a sound rim to re cover. We unfortunately cannot repair any broken or damaged metal work, spokes, splines or bosses

We are not offering an exchange service, you will receive your wheel back with spokes & centre boss in the same condition that we receive it.